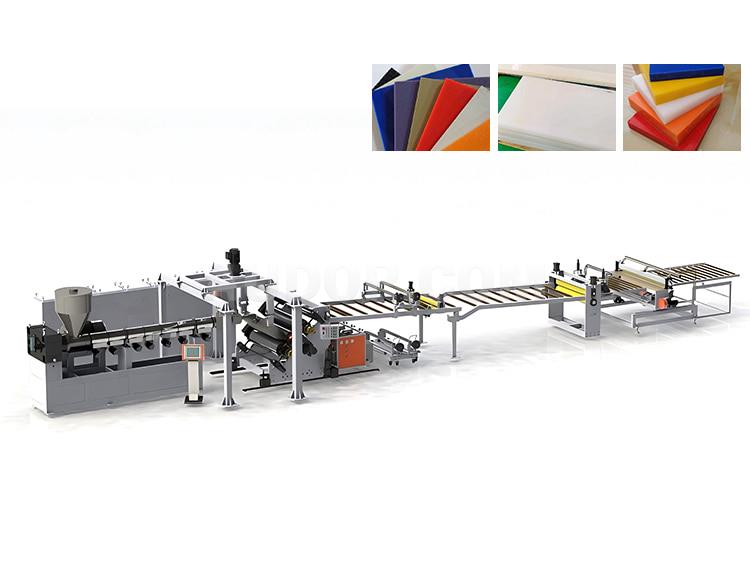

PP PE ABS PVDF PVC Thick Plate Extrusion Line

Features

Product Features

High-Efficiency Production & Thick Sheet Adaptability

• Enables continuous extrusion of ultra-thick sheets with optimized energy efficiency ratios.ultra

• Optional tandem extrusion technology supports specialized sheet processing (e.g., glass fiber-reinforced sheets).

Precision Process Control

• Intelligent temperature control and pressure feedback systems ensure uniform thickness, smooth surfaces, and minimal material waste.

• A multi-stage flow channel design combined with an adjustable three-roll calibration system enhances dimensional accuracy. multi-stage flow

Durability & Full Automation

• Core components are made of corrosion-resistant materials and coated with advanced technology to extend equipment service life.

• Integrated rapid mesh changing, automatic cutting, and stacking systems reduce manual intervention and achieve full automation.

Flexible Configuration & Scalability

• Supports vertical/inclined rolling machines and coil/sheet winding devices for diverse production scenarios.

• Scalable multi-layer co-extrusion and laminating functions meet special requirements, including high barrier performance and weather resistance.

Overview

Line Configuration

• Extruder:

A single-screw extruder is selected based on material characteristics, offering high output and excellent plasticizing performance.

• Screen Changer:

This hydraulically controlled device enables rapid screen replacement with a dual-position and multi-screen design. The sealing mechanism prevents material leakage, ensuring stable extrusion. publically controlled device enables rapid screen replacement with a dual-position and multi-screen design

• Pressure Feedback:

Equipped with branded sensors, the system stabilizes pressure effectively, enhancing production efficiency and product consistency while improving sheet thickness uniformity.

• Extrusion Die:

The single-layer and multi-layer composite co-extrusion die features a hanger-style structure. Its interior is polished and coated with a hardened layer to ensure stable material flow and superior surface finish. multi-layer composite co-extrusion die features a hanger-style structure. Its

• Three-Roll Calendar:

With a vertical or inclined configuration, each roll is independently temperature-controlled via water/oil circulation. The system achieves precise temperature management and synchronized roll speed through frequency conversion, simplifying thickness adjustment. ulation. The system achieves precise temperature management and synchronized roll speed through

• Haul-off:

The two-roll design with frequency-conversion speed regulation maintains an optimal tension-to-speed ratio for the plate, ensuring operational safety and product stability.

• Automatic Cutting System:

A servo motor-driven cutting mechanism with an automatic length counter guarantees fast, precise cuts and consistent plate flatness.

• Electrical Control System:

Multiple control systems, including PLC-based automation and standard speed regulation modes, are available to accommodate diverse operational needs.

Material & Industry Applications

• PP Sheets: Lightweight, non-toxic, and corrosion-resistant—ideal for chemical, food, medical, and electronics sectors.

• PE Sheets: Superior chemical resistance for industrial equipment, water treatment, and sports infrastructure.

• ABS Sheets: High-impact and heat-resistant solutions for appliances, packaging, and medical devices.

• PVDF Sheets: Ultra-pure, additive-free sheets for semiconductor, chemical transfer, and high-purity systems.

• PVC Sheets: Rigid and transparent options for signage, corrosion-resistant equipment, and construction.

After-Sales Support

• Training: Comprehensive operational and maintenance guidance.

• Rapid Response: Dedicated technical support and spare parts supply to minimize downtime.

• Remote Assistance: 24/7 troubleshooting via expert engineers.

• Customization: Tailored configurations for unique material or industry requirements.

Technical Parameters

Technical Parameters

| Single screw -120 | Single screw -150 | Single screw -180 | Cone twin screw-80/156 |

| ABS、PP、HDPE、PVDF | ABS、PP、HDPE、PVDF | ABS、PP、HDPE、PVDF | PVC |

| 3mm - 50mm | 3mm - 50mm | 3mm - 50mm | 3mm - 30mm |

| 1200mm | 1800mm | 2000mm | 1220mm |

| 300KG/H - 400KG/H | 450KG/H - 550KG/H | 500KG/H - 700KG/H | 350KG/H - 450KG/H |

Your requirements are the basis for our development and a daily challenge to bring to fruition, please do not hesitate to inquiry us.